STEEL PLANT EQUIPMENT’S

According to the report from World Steel Organisation, more than 60% of production costs (times, buffer stocks and quality losses, energy and safety) are directly or indirectly affected by the efficiency and effectiveness in operation and maintenance activities within a Steel Manufacturing Unit.

Modernized steel manufacturing plants are equipped with the most technologically advanced heavy machinery that can be used to produce their own steel products. These machines form an assembly line for the products that is then processed step by step to produce finished steel goods. While the specific processes may affect the properties and operation of each unit, the overall purpose of the units is the same. Their proper functioning is what ensures the quality of the unit’s outputs.

This is a list of all the heavy machinery that is used in steel plant manufacturing plants

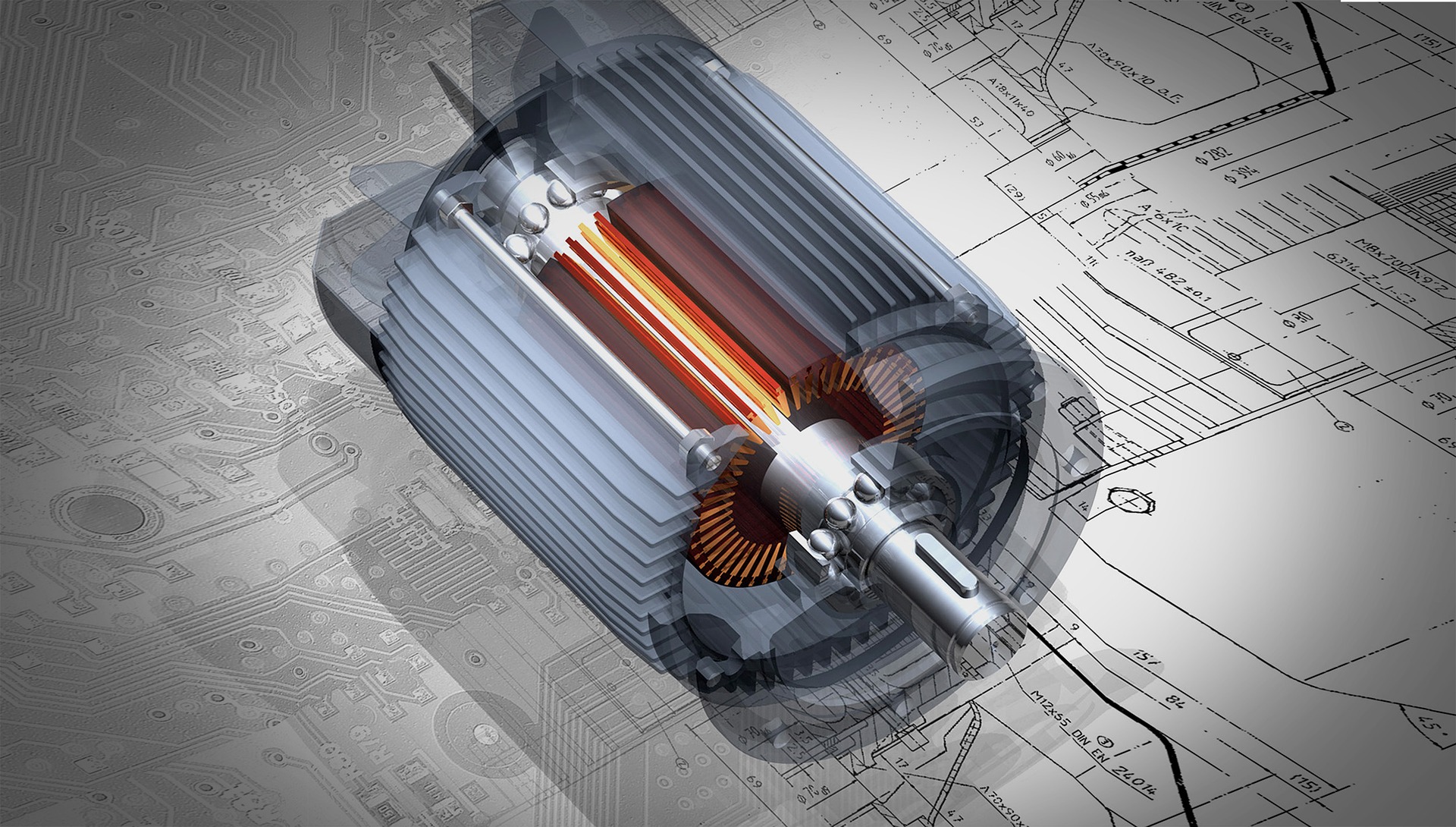

General Industrial Technology

A steel plant will include a variety of machines, such as conveyor belts and motors, heaters, boilers, boilers, heat recovery units, exhausts, heat recovery units, heat pumps, pipes, cranes, and many other basic machines. These tools are not only required for steel industries but can be used in any type of manufacturing facility. These tools are used to facilitate the handling of the process or secondary operations such as heating and transporting. They are used to connect individual machinery.

Rolling Mill

A rolling mill is used in a steel plant to hot-roll the steel bars/billets uniformly without any defects or impurities. To shape steel products, the rolling mill uses cylindrical rollers in opposing pairs and against flat plates. A roughing mill train, intermediate and finishing mill trains are all part of the rolling mill. They can be operated continuously with D.C. drives. This is used by major Steel plants primarily to convert billets into high-quality TMT Steel bars through heat, pressure, and subsequent quenching.

Quench Box

Quenching is the process of cooling a hot metal quickly to increase its strength and hardness. This is done by exposing it to fresh water. At regular intervals, freshwater is injected into the nozzles. These nozzles are evenly spaced along the cooling lengths of the rod. Quench box is a complex piece of machinery that handles near-melting steel temperatures and cools them with water. The quench box quality determines how much quenching the rod is exposed to. This in turn influences the layers that determine its physical properties.

There are many other types of machinery available, such as CCM (Continuous Casting Machine), Straightening Machines, Loopers, and Girders, as well. These machines are used only in the steel industry for their specific purposes. The best quality end products are possible only if the facility is properly maintained and operated.

These are essential for the production and use of steel goods because they have a direct impact on the composition, strength, endurance as well as uniformity, ductility, etc. Many advancements have allowed for the improvement of the process through the use of advanced technologies.