Product and Services

Steel Plant Equipment

According to the report from World Steel Organisation, more than 60% of production costs (times, buffer stocks and quality losses, energy and safety) are directly or indirectly affected by the efficiency and effectiveness in operation and maintenance activities within a Steel Manufacturing Unit.

Modernized steel manufacturing plants are equipped with the most technologically advanced heavy machinery that can be used to produce their own steel products. These machines form an assembly line for the products that is then processed step by step to produce finished steel goods. While the specific processes may affect the properties and operation of each unit, the overall purpose of the units is the same. Their proper functioning is what ensures the quality of the unit’s outputs.

This is a list of all the heavy machinery that is used in steel plant manufacturing plants.

General Industrial Technology

A steel plant will include a variety of machines, such as conveyor belts and motors, heaters, boilers, boilers, heat recovery units, exhausts, heat recovery units, heat pumps, pipes, cranes, and many other basic machines. These tools are not only required for steel industries but can be used in any type of manufacturing facility. These tools are used to facilitate the handling of the process or secondary operations such as heating and transporting. They are used to connect individual machinery

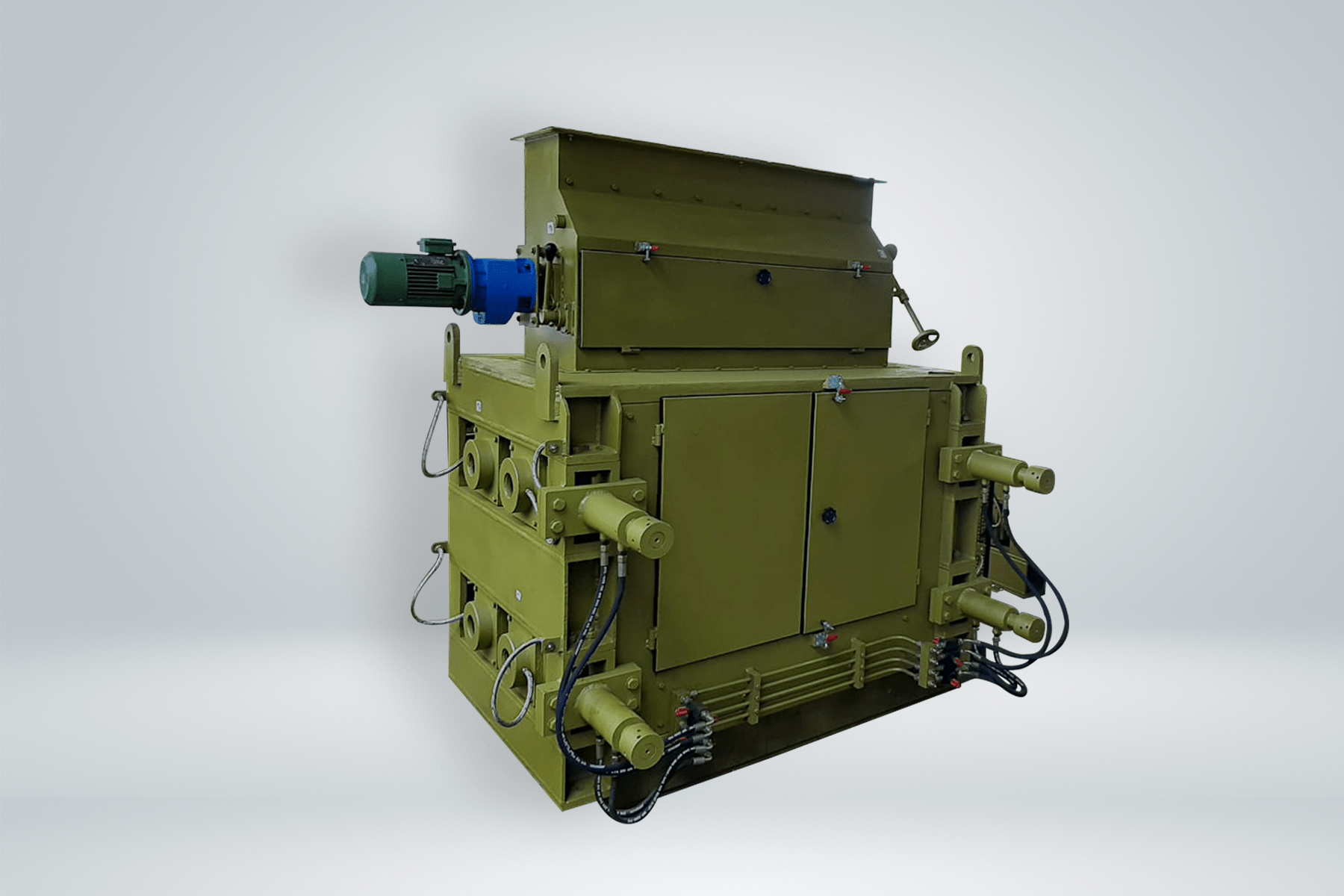

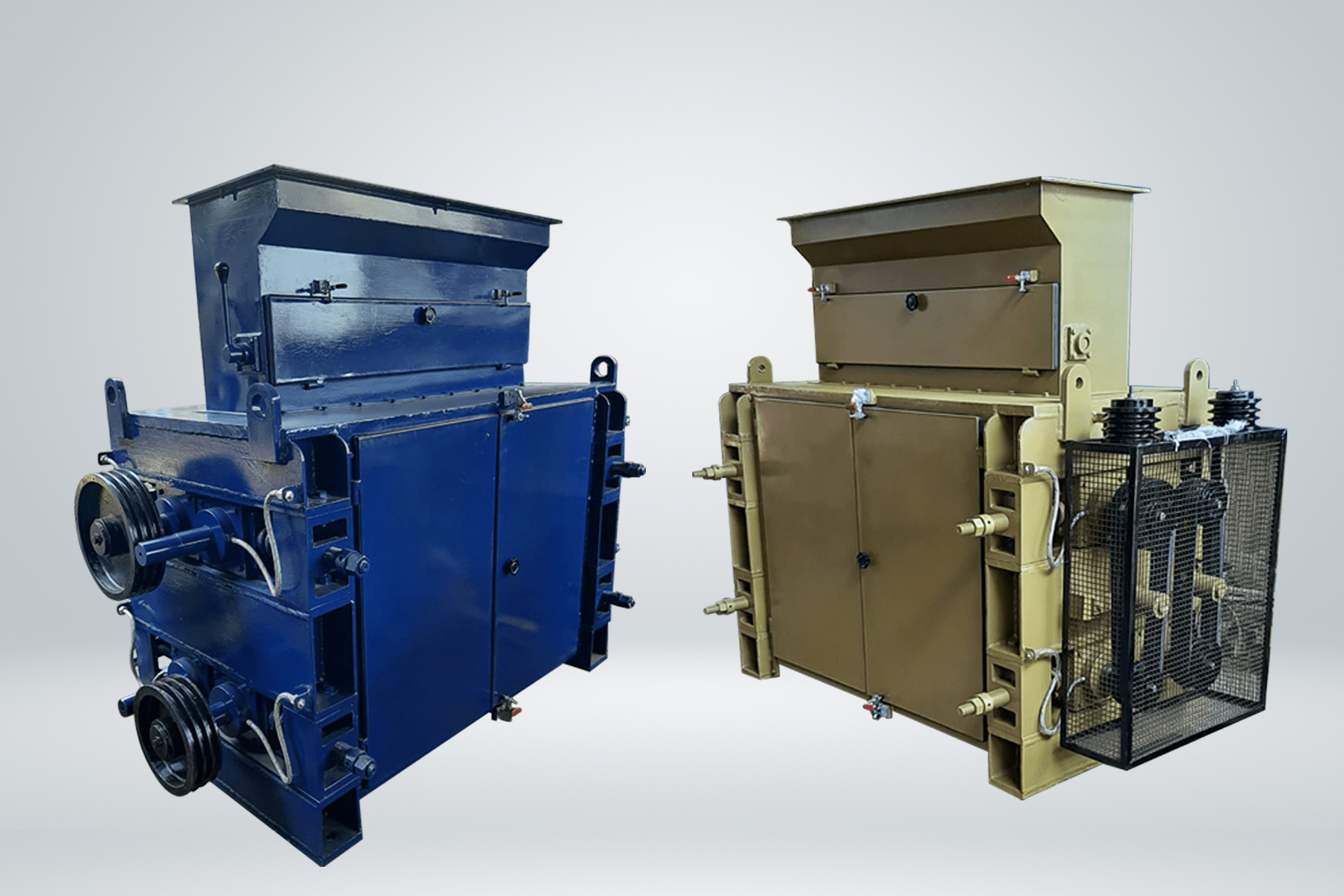

Rolling Mill

A steel plant will include a variety of machines, such as conveyor belts and motors, heaters, boilers, boilers, heat recovery units, exhausts, heat recovery units, heat pumps, pipes, cranes, and many other basic machines. These tools are not only required for steel industries but can be used in any type of manufacturing facility. These tools are used to facilitate the handling of the process or secondary operations such as heating and transporting. They are used to connect individual machinery

Quench Box

There are many other types of machinery available, such as CCM (Continuous Casting Machine), Straightening Machines, Loopers, and Girders, as well. These machines are used only in the steel industry for their specific purposes. The best quality end products are possible only if the facility is properly maintained and operated.

These are essential for the production and use of steel goods because they have a direct impact on the composition, strength, endurance as well as uniformity, ductility, etc. Many advancements have allowed for the improvement of the process through the use of advanced technologies.

Material Handeling Equipment

Material handling machinery ( MHE) is mechanical equipment that is used to move, store,

control and protect materials, goods, and products during the manufacturing, distribution,

consumption, and disposal process. There are four main categories of equipment: transport

equipment; positioning equipment; unit load formation equipment; and storage equipment.

Conveyors

Conveyors can be used to move material frequently over a fixed path. They can also be classified by the product being transported: bulk or unit load, the location of the conveyor (in-floor, overhead or on-floor), and whether loads can accumulate on the conveyor. While conveyors can move multiple units simultaneously, accumulation allows for intermittent movement of each unit. The flat belt and the roller are both unit-load on floor conveyors. However, the roller has accumulation capability. In the same way, the power-and-free and trolley overhead conveyors are unit-load overhead conveyors. The power-and free is designed to add an additional track to give the trolley the accumulation ability.

Cranes

Conveyors can be used to move material frequently over a fixed path. They can also be classified by the product being transported: bulk or unit load, the location of the conveyor (in-floor, overhead or on-floor), and whether loads can accumulate on the conveyor. While conveyors can move multiple units simultaneously, accumulation allows for intermittent movement of each unit. The flat belt and the roller are both unit-load on floor conveyors. However, the roller has accumulation capability. In the same way, the power-and-free and trolley overhead conveyors are unit-load overhead conveyors. The power-and free is designed to add an additional track to give the trolley the accumulation ability.

Pallet Jack

Product Design And Development

Consumers today are more concerned about product design, performance, interconnectivity, and interoperability. Product aesthetics, ease of use, form factor, durability, and product performance are all important factors in a consumer’s purchase decision. All aspects of product design are covered by product design services. It is complex because it involves optimizing and developing design, validating mechanical design, and prototyping superior products.

Metal-India is a one-stop solution provider that offers complete mechanical engineering services, from concept to production. Metal-India helps businesses avoid the challenges that come with modern design, including overhead costs, in-house capabilities, multiple vendors, and complex designs. We have years of experience in product innovation and product excellence, which allows us to assist our clients through the entire cycle of creating innovative products with reduced lead time and better ROI.

On the other hand, development involves finding new market opportunities and creating products that meet the needs of the chosen market. The development process focuses on refining and modifying products until they are ready for testing.

Our specialty

- We have a deep understanding of the Product Design Lifecycle, which allows us to better incorporate your ideas into product development. We have direct experience in every step of the process, from conceptualization to prototype development, testing, and finally manufacturing.

- We have access to advanced testing tools and facilities, such as Finite elements analysis and CFD. Furthermore, we are proficient in both actual and virtual testing that is done during simulation.

- We are able to design products within the budget that the client has set because of our knowledge and expertise in the manufacturing process. A thorough understanding of the manufacturing process is key to our manufacturing solutions. This allows us to take care of all the requirements.

- Our expertise is in project management. We use our skills in resource estimation, allocation, budgeting, controlling execution and managing cross-functional teams to ensure the successful implementation of projects.

Building Costruction And Planning

Our clients have direct access to highly-qualified and experienced specialists who offer consultancy services in pre-work, building design, construction management, construction supervision, and maintenance. Metal India has been an engineering consultant for almost all types of building projects, including domestic housing, schools and hotels, offices, factories, health centers, sports centers, and offices.

Metal India specialists have the expertise to tackle any project challenge, from preliminary or structural design for buildings and other structures to the design and implementation of electrical and HVAC control systems and fire safety plans, as well as the development of a variety of acoustical solutions.